- Shop

- Cedar Pergola Kits | 8'x8' and 10'x10'

-

Kalamalka Pergola Kit | 10'x10'

Kalamalka Pergola Kit | 10'x10'

Kalamalka Pergola Kit | 10'x10'

Cedarshed Canada

Couldn't load pickup availability

Free shipping over $50

View full details

|

Cedarshed is excited to introduce “The Kalamalka” pergola kit. Stylish and functional, these cedar pergolas have been crafted to provide you with just the right amount of shade. Designed with the DIY’er in mind, the Kalamalka pergola requires limited building experience and will take about a day for two people to assemble. Free Shipping, Always! The Kalamalka Pergola Kit Features: Manual: Essential Information: |

Collapsible content

Materials

Floor: Pre cut 2x4 western red cedar floor joists, 12” spacing. Pre cut 5/8” plywood

Walls & Roof framing: 2x3 SPF (spruce, pine, fir)

Exterior: Western red cedar bevel siding

Windows: 1/8” plexi glass

Shipping information

Shipments will be delivered to or as close to the purchasers property line and or driveway provided the location is deemed assessable by the delivering carrier. It is the Purchasers responsibility to inform Cedarshed at time of purchase of any unusual or difficult location or delivery issues so necessary arrangements may be made with the delivering carrier where possible. Most deliveries can be lift gated from the truck to the curb or driveway. In some cases, the carrier's terminal may not have the necessary equipment or be able to safely liftgate depending on the unique delivery situation. In this case the product can be unloaded by hand with two people in 15-30 minutes by removing the paper wrap and cutting the plastic straps.

Cedarshed's "Suggested Retail Price" includes the cost of shipping and delivery to Standard Motor Freight and UPS/FED-EX services. Shipping policy listed is pertaining to continental US only. AK and HI customers need to call in to discuss ocean freight options.

Delivery

The average lead time is 3-4 weeks from time of order to delivery. This can vary, and under certain circumstances lead times can shorten or lengthen. Spring & Summer lead times can be longer. Please reach out for accurate lead times at the time of order.

We assure you that we do our best to have your order shipped the earliest time possible, and a tracking # will be emailed to you as it ships.

When the order arrives at your local delivery terminal, they will call ahead to set up a delivery window.

Alternatively, you can call the carrier with the tracking number to discuss delivery timeline prior to delivery.

Warranty

OUR COMMITMENT TO YOU We understand that a Cedarshed product may well be a major purchase for you. We want you to be aware of our Warranty Policy so you feel comfortable and confident that you’ve made the right decision. "All Structures purchased directly from Cedarshed are covered for a period of one year for defects in manufacturing and workmanship." In addition to this, if you are missing or have received a broken piece, simply call our Cedarshed Customer Support Line @ 1-800-830-8033. After we determine how to solve the problem to your satisfaction, we will be happy to replace the part(s) free of charge. The replacement part(s) should be couriered or shipped from our premises within ten (10) business days of receipt of the purchaser’s notification. It is the purchaser’s responsibility to notify Cedarshed Industries, within 14 days after receiving the product, of any broken or missing pieces. Failure to do so will void Cedarshed’s obligation to send parts out free of charge. If you cannot confirm that all pieces are intact and in good shape within the allotted time period, it is the purchaser’s obligation to notify Cedarshed in writing of your situation so that a longer grace period may be granted. Such extension requests, and approval by Cedarshed Industries, must be in written form.

Foundation preparation

HOW TO BUILD YOUR SHED FOUNDATION

Cedarshed recommends three different methods for constructing basic foundations for all our cedar products:

• Patio Stones

• 4x4 Pressure Treated Beams

• Concrete Slab

We Highly Recommend the Following "Step-By-Step" Procedures:

|

1 / Preparing the Site for Construction

Make sure the ground slopes away from the site at least 10 feet in all directions. If necessary, build up the soil in the center of the site and slope away for the high point to provide drainage. Fill in any low spots within the perimeter of the site. A slope of 1/8 inch per foot is enough to prevent water accumulation. |

|

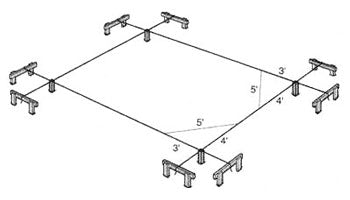

2 / Laying Out the Foundation No matter which type of foundation you’ve chosen, start by outlining the "footprint" on the site. Start by choosing one corner of the garden shed and mark it (A) by driving a stake into the ground. GARDEN SHEDS 3-4-5 Triangulation Method Run a second line perpendicular to the first across point A. Mark point C 4ft. from point A. Move line AC so that the distance BC is exactly 5 ft. Angle BAC is now 90 degrees. Set up batter boards and guide lines to outline the entire shed, making right angles at each corner using the 3-4-5 triangle method described |

|

3/ Determining The Type Of Foundation 1. PATIO STONE FOUNDATION GARDEN SHEDS: Starting with one floor section, position stones around its perimeter and specific joists. (For details, see specific instruction manual) Use a 2x4 straight piece of lumber on edge and a carpenter’s level to position correctly. Add or remove soil/sand under each stone until level. Complete remaining floor sections in the same manner. When all floor panels are level with each other, flip over, screw together and place back on level foundation. 2. 4x4 PRESSURE TREATED BEAM FOUNDATION To prevent the beams from shifting, secure them with a 1/2" inch rebar inserted through holes drilled in the beams and driven 3 to 4 feet into the ground. Leave each side or end of the foundation open to promote drainage and air circulation beneath the floor. 3. CONCRETE SLAB FOUNDATION Using either mix your own concrete of having it delivered by truck, ready to pour, depends on how much time and effort you have to dedicate to the project. A slab for our 8x10 foot Rancher to a depth of 4 inches will require approximately 1 cubic yard of premixed concrete. Use the following procedure: 2. Excavate the slab area to a depth 6 inches. This would put the finished slab surface 2 inches above ground (4 inches of gravel) 3. Set up your batter board strings to represent the outside face of the slab. At each corner, drop a plumb line from the intersecting strings to the bottom of the trench, then drive a 2x4 stake at this point. Using the plumb bob again, drive a nail into the top of the stake where the plumb bob touches it. Attach strings between the stakes. Using the strings as guides, drive the 2x4 form stakes around the trench perimeter, spaced on 2 foot centers. 4. Attach the form boards to the stakes with double-headed nails. Make sure the stakes are on the outside of the boards and flush with or below them. 5. Use 2x4 stakes to brace the corners of the forms. 6. Backfill the excavation with 4 inches of gravel, then lay down a plastic vapor barrier. 7. Spread or pour concrete with a rake or hoe, compacting it gently into the footing areas. Use a shovel to move concrete into footing trench. Make the pour to about 1 inch above the forms to allow for settling. Use a long 2x4 to level the concrete. Move the board in a side-to-side motion as you pull it towards you. 8. Use finishing tools, such as a bull float and trowel, to smooth the concrete surface. Allow the concrete to cure fully (seven to ten days).

|

Our Customer Feedback

"After a lot of sweat and a little bit of blood lost the new cedar shed is complete! The best service and support I've ever experienced, would highly recommend Cedarshed Industries"

Tyson Lomerts

Facebook Review

"I tell you I'm sure impressed with your product. This is my music studio"

Roderick Duncan

Facebook Review

"I love my shed! That side yard has weird 90's angles at the back and the shed blocks that as well as being nice to look at and providing a ton of storage!"

Kjersti Sivitilli

Facebook Review

"I put a CedarShed Sunshed in last spring. l have grown so many seedlings in it this spring, it is fabulous!"

Isla Viscount

Facebook Review

"I am amazed that in this day and age there still exists a company that delivers EXACTLY what they advertise — and more!"

J. Pullen

Parksville, BC

"My Contractor estimated that he would have charged me double the amount I paid, if he had to build a similar garden shed from scratch."

John L.

Montara, California

"Everyone that helped me put it together and everyone in my family has been very impressed with how I found such a nice-looking little garden shed. It looks so nice, settled in with our four redwoods. It makes such a good clubhouse for the grandchildren."

Rudy D.

Palo Alto, California

"You have an excellent product. I had a lot of fun building this Longhouse."

P. Bell

"I was very impressed with how easily all the parts fit together. Not a single problem. Thanks!"

Neal R.

Glendale, Missouri

"I wanted to send a note to let you know that our shed arrived last Friday and my son and I assembled it over the weekend. It came out great! Everything was first rate from the quality of the packaging (very impressive that you neatly packed it on one skid) to cedar and the precision of the cut components… Thank you for your assistance throughout. A very satisfied customer."

Ralph D.

Chicago, IL

"In 1996 we bought one and as far as I know it's still standing. I sold in 2018 and was still in great shape even came with cedar shake roof"

Diana Benoit

Facebook Review